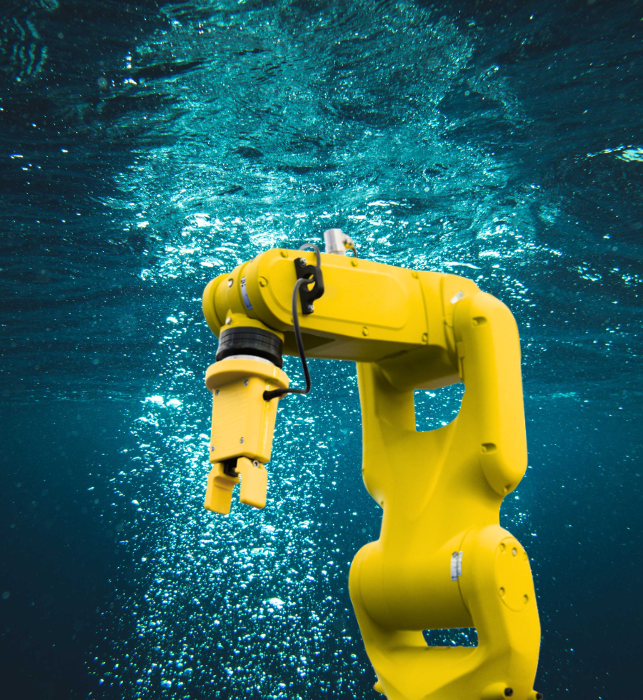

In the fast-evolving landscape of small and medium-sized business (SMB) manufacturing, the adoption of agentic AI is revolutionizing quality management systems (QMS). Intelligence QMS, a cutting-edge platform, empowers manufacturers to streamline operations, enhance product quality, and scale efficiently without proportional increases in resources. By leveraging autonomous AI agents, SMBs are overcoming traditional constraints—such as limited workforce and complex compliance demands—redefining operational excellence in the digital era.

This 1,200-word blog explores how Intelligence QMS is driving this transformative shift, with real-world case studies, actionable insights, and a roadmap for adoption.

The Challenges Facing SMB Manufacturers

SMB manufacturers operate in a high-stakes environment where quality, efficiency, and compliance are non-negotiable. Yet, they face unique hurdles that hinder scalability and competitiveness:

- Resource Constraints: Limited budgets and staffing—often fewer than 50 employees—restrict investment in advanced systems, with 62% of SMBs citing cost as a barrier to technology adoption.

- Regulatory Complexity: Strict standards, such as ISO 9001 or FDA regulations, demand rigorous documentation and audits, consuming 20-30% of operational time.

- Data Overload and Silos: Disparate systems for production, quality control, and supply chain create inefficiencies, with 70% of manufacturers reporting data integration issues.

- Skilled Labor Shortages: A projected shortfall of 2.1 million manufacturing jobs by 2030 exacerbates the challenge of maintaining quality without specialized expertise.

These pressures elongate quality assurance cycles, increase defect rates, and limit agility, making traditional QMS solutions inadequate for modern demands.

Intelligence QMS: A New Paradigm in Quality Management

Intelligence QMS harnesses agentic AI—autonomous systems capable of perceiving, reasoning, and acting—to transform quality management. Unlike conventional QMS platforms that rely on manual inputs and static rules, Intelligence QMS deploys AI agents to orchestrate end-to-end processes, from real-time monitoring to compliance reporting. Built on a scalable cloud architecture, it integrates with existing ERP and IoT systems, enabling SMBs to achieve enterprise-grade outcomes with lean teams.

Key features include:

- Real-Time Quality Monitoring: AI agents analyze production data from sensors and logs, detecting anomalies instantly to reduce defects by up to 40%.

- Automated Compliance: Agents generate audit-ready reports, ensuring adherence to standards like ISO 13485, saving 15–20 hours weekly on documentation.

- Predictive Maintenance: Machine learning models forecast equipment failures, cutting downtime by 30% and extending asset life.

- Scalable Workflows: Low-code customization allows non-technical staff to configure agents, reducing reliance on IT specialists.

This agentic approach collapses the gap between quality issues and resolution, enabling SMBs to compete in high-precision industries like aerospace, medical devices, and automotive.

The Benefits of Agentic AI in SMB Manufacturing

By embedding Intelligence QMS, manufacturers unlock transformative advantages that address core pain points and drive growth in the digital economy.

- Enhanced Quality Control: Real-time defect detection and root cause analysis improve product consistency, with 85% of adopters reporting reduced scrap rates.

- Operational Efficiency: Automation of repetitive tasks—like data entry and audit preparation—saves 25 hours monthly per employee, per industry benchmarks.

- Cost-Effective Scaling: AI agents enable SMBs to handle 3x production volumes without proportional headcount increases, with 78% of users citing scalability as a top benefit.

- Compliance Agility: Dynamic reporting adapts to evolving regulations, reducing non-compliance risks by 50% compared to manual systems.

- Competitive Edge: High-growth SMBs using AI report 20% faster time-to-market, outpacing larger rivals.

These benefits position Intelligence QMS as a catalyst for the “Idea Economy,” where innovative processes, not resource volume, drive success.

Real-World Case Studies: Intelligence QMS in Action

The impact of Intelligence QMS is best illustrated through SMB manufacturers who have leveraged its capabilities to achieve remarkable outcomes.

PrecisionMed: Elevating Medical Device Quality

PrecisionMed, a 40-employee medical device manufacturer, faced challenges meeting FDA 21 CFR Part 820 standards due to manual QMS processes. By implementing Intelligence QMS, they deployed AI agents to monitor production lines for catheter components, detecting micro-defects in real-time via IoT sensors. Agents also automated CAPA (Corrective and Preventive Action) workflows, reducing resolution time from days to hours.

Outcomes:

- 35% reduction in defect rates, enhancing product reliability.

- 60% faster compliance reporting, saving 10 hours weekly.

- Scaled production 2x without additional staff, supporting a new product launch.

PrecisionMed’s lean team now rivals larger competitors, proving agentic AI’s role in leveling the playing field.

AeroTech Components: Streamlining Aerospace Manufacturing

AeroTech, a 25-person aerospace parts supplier, struggled with ISO 9001 audits and supply chain inefficiencies. Intelligence QMS agents integrated with their ERP system to predict material shortages and automate quality checks for machined components. Predictive maintenance agents reduced equipment downtime by 28%, while compliance agents generated audit trails instantly.

Outcomes:

- 50% reduction in audit preparation time, ensuring ISO certification.

- 20% decrease in production delays, improving delivery timelines.

- 15% cost savings from optimized material use.

AeroTech’s agility allowed it to secure contracts with major aerospace firms, showcasing how AI drives competitiveness.

GreenPack Solutions: Sustainable Packaging Innovation

GreenPack, a 30-employee sustainable packaging SMB, used Intelligence QMS to enhance quality for biodegradable materials. AI agents analyzed production data to optimize molding processes, reducing waste by 30%. Automated compliance reporting ensured adherence to environmental standards, while predictive analytics forecasted demand, enabling just-in-time inventory.

Outcomes:

- 25% improvement in material efficiency, boosting sustainability.

- 40% faster response to regulatory audits, avoiding fines.

- 3x order capacity handled by existing staff, supporting rapid growth.

GreenPack’s success highlights how Intelligence QMS aligns quality with environmental and business goals.

These cases underscore a common theme: Intelligence QMS empowers SMBs to achieve enterprise-grade quality and efficiency with minimal resources.

Strategic Roadmap: Implementing Intelligence QMS

Adopting Intelligence QMS requires a structured approach to maximize ROI while mitigating risks. SMBs can follow this roadmap to integrate agentic AI effectively:

- Assess Current Systems: Conduct a gap analysis to identify quality bottlenecks, such as manual inspections or compliance delays. Prioritize areas with high defect rates or regulatory exposure.

- Select Integration Points: Ensure compatibility with ERP, IoT, and CRM systems. Intelligence QMS’s API-driven architecture supports seamless integration with platforms like SAP or NetSuite.

- Pilot and Customize: Start with a single process, such as defect detection, using low-code tools to configure agents. Train on historical data to refine accuracy, targeting 90% anomaly detection rates.

- Ensure Governance: Implement safeguards for data security and compliance, aligning with GDPR or FDA standards. Regular audits and human oversight prevent bias or errors.

- Scale and Measure: Expand to additional workflows, tracking KPIs like defect reduction (aim for 30-40%), time savings (20+ hours/month), and ROI (expect 6–12 months payback).

- Train Teams: Upskill staff via Intelligence QMS’s training modules, addressing the 65% of SMBs concerned about AI skill gaps.

Challenges like initial costs or data integration can be mitigated through phased rollouts and partnerships with AI consultancies, ensuring a smooth transition.

Addressing Common Concerns

SMBs often hesitate due to misconceptions about AI complexity or cost. Intelligence QMS counters these:

- Affordability: Subscription models start at $5,000/year for basic tiers, with modular pricing for scaling.

- Ease of Use: Low-code interfaces enable non-technical staff to deploy agents, with 80% of users reporting setup within weeks.

- Security: Built-in encryption and compliance tools address 70% of SMBs’ data privacy concerns.

These features make Intelligence QMS accessible and secure for resource-constrained manufacturers.

Conclusion: Leading the AI-Driven Manufacturing Revolution

Intelligence QMS is redefining SMB manufacturing by embedding agentic AI into the core of quality management. By addressing resource limitations, compliance burdens, and data challenges, it empowers lean teams to achieve unparalleled quality and efficiency. Real-world successes like PrecisionMed, AeroTech, and GreenPack demonstrate that SMBs can lead in high-stakes industries, turning constraints into competitive advantages.

In the Idea Economy, where innovation trumps capacity, Intelligence QMS is the catalyst for growth. Manufacturers must act swiftly—start with a pilot, measure outcomes, and scale boldly. As 83% of high-growth SMBs embrace AI experimentation, those leveraging Intelligence QMS will not only survive but thrive, setting new benchmarks for manufacturing excellence in the digital age.